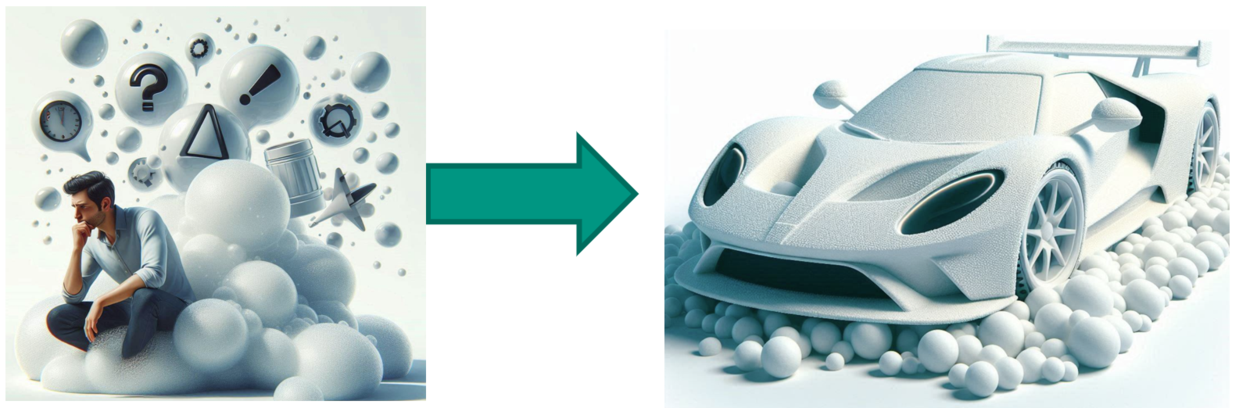

Modeling polymer foams for more sustainable mobility

Motivation

Thermoplastic foams are a key technology for increasing the sustainability of modern mobility in several aspects. On the one hand, they are an excellent lightweight construction material, which helps to reduce CO2 emissions through weight reduction, but at the same time they are also simpler and easier to recycle compared to conventional PU foams.

The foam structure created during production significantly influences the thermo-mechanical behavior of the foam and must therefore be known for a good design. In order to be able to predict the subsequent properties of the foam without a high experimental effort, a simulation is indispensable. As part of the work, state-of-the-art simulations are to be tested and expanded in order to be able to simulate foam formation. The simulative results are to be validated with experimental investigations.

Contents:

- Familiarization

- Model implementation

- Independent execution and evaluation of simulations

- Validation of the simulation results

Requirements profile:

- Degree in mechanical engineering, mechatronics or similar

- Interest in polymers and simulation

- Programming experience (Python, Matlab, C++ or similar) advantageous but not necessary

- Structured, goal-oriented way of working

Start: immediately

Application: Please send your CV and transcript of records to the contact email address

Contact: Dr.-Ing. Florian Wittemann, Email: florian.wittemann∂kit.edu