Forming

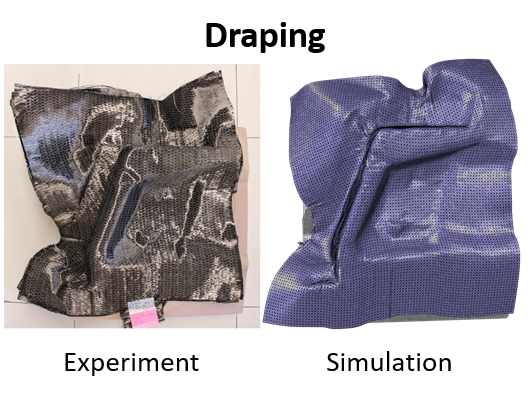

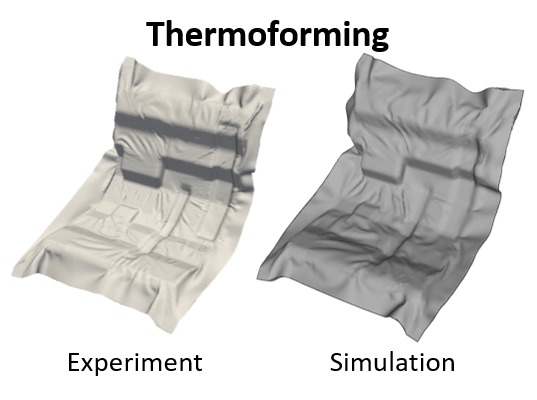

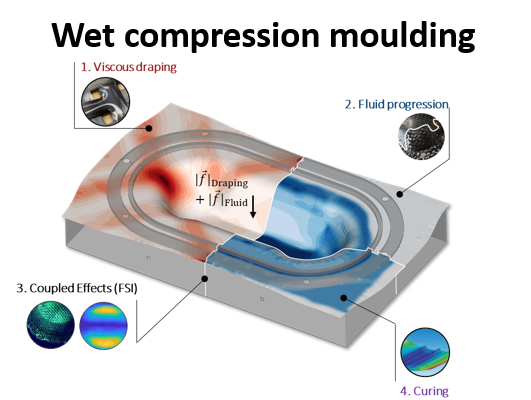

In the field of forming simulation, methods for the prediction of the forming behaviour of textile and pre-impregnated semi-finished products are developed. Our institute focuses on dry woven or non-crimp fabrics, unidirectionally reinforced thermoplastic tapes (UD-Tapes) as well as on the combination of textile draping and infiltration in one process step, which is especially relevant for wet compression moulding. For the macroscopic description of the semi-finished products during processes, we develop methods for forming simulation by implementing suitable finite user-elements, material models and contact models, based on the commercial FE solver Abaqus. In addition, state of the art methods for the characterization of semi-finished products are conducted in cooperation with the KIT-IAM-WK and Fraunhofer ICT, and customized characterization methods are developed for new material systems.

Research focus

- Efficient macroscopic simulation models for component forming

- Prediction of forming effects and defects (e.g. fiber orientation, wrinkling, gapping)

- Development of suitable material models considering the anisotropic membrane and bending behavior of semi-finished products

- Thermomechanical and rate-dependent modelling of UD-tapes considering crystallization kinetics (cooling)

- Strong fluid-structure interaction for the infiltration during wet compression processes

- Efficient consideration of mesoscopic effects (e.g. fibre bending) on a macroscopic scale

- Development of three dimensional modelling approaches to consider compaction during forming simulations

Research projects |

Contact

M.Sc. Bastian Schäfer

M.Sc. Johannes Mitsch

M.Sc. Jan Paul Wank

|

Selected publications in the research field

Schäfer, B.

2024, November 6. 10. Technologietag Leichtbau (2024), Stuttgart, Germany, November 6, 2024

Schäfer, B.; Dörr, D.; Zheng, R.; Naouar, N.; Kärger, L.

2024, September 11. 15th TexComp : Coming back home (2024), Leuven, Belgium, September 11–13, 2024

Schäfer, B.; Zheng, R.; Colmars, J.; Platzer, A.; Naouar, N.; Kärger, L.

2024, June 24. doi:10.5281/zenodo.12516897

Schäfer, B.; Zheng, R.; Colmars, J.; Platzer, A.; Naouar, N.; Boisse, P.; Kärger, L.

2024. Composites Part B: Engineering, 287, 111765. doi:10.1016/j.compositesb.2024.111765

Schäfer, B.; Dörr, D.; Zheng, R.; Naouar, N.; Kärger, L.

2024. Composites Part A: Applied Science and Manufacturing, 185, Art.-Nr.: 108359. doi:10.1016/j.compositesa.2024.108359

Poppe, N.; Zeeb, G.; Wittemann, F.; Wilhelm, M.; Kärger, L.

2024, July 3. 21st European Conference on Composite Materials (ECCM 2024), Nantes, France, July 2–5, 2024

Schäfer, B.; Kärger, L.; Naouar, N.; Zheng, R.

2024. Technische Informationsbibliothek Hannover. doi:10.34657/13755

Schäfer, B. B. J.

2024, May 27. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000170739

Miranda Portela, R.; Schäfer, B.; Kärger, L.; Rocha de Faria, A.; Montesano, J.

2024. Material Forming: ESAFORM Toulouse, 2024 : the 27th International ESAFORM Conference on Material Forming -ESAFORM 2024- held in Toulouse, France, April 24-26, 2024, 494–502, Materials Research Forum LLC. doi:10.21741/9781644903131-55

Schäfer, B.; Naouar, N.; Kärger, L.

2024. Material Forming: ESAFORM Toulouse 2024 : the 27th International ESAFORM Conference on Material Forming -ESAFORM 2024- held in Toulouse, France, April 24-26, 2024, Ed.: Araujo, Anna Carla; Korycki, Adrian; Olivier, Philippe, Schmidt, Fabrice, 540–548, Materials Research Forum LLC. doi:10.21741/9781644903131-60

Zheng, R.; Naouar, N.; Schäfer, B.; Platzer, A.; Colmars, J.; Kärger, L.; Boisse, P.

2024. Material Forming: ESAFORM Toulouse 2024 : the 27th International ESAFORM Conference on Material Forming -ESAFORM 2024- held in Toulouse, France, April 24-26, 2024, Ed.: Araujo, Anna Carla; Korycki, Adrian; Olivier, Philippe, Schmidt, Fabrice, 623–630, Materials Research Forum LLC. doi:10.21741/9781644903131-69

Zheng, R.; Naouar, N.; Colmars, J.; Platzer, A.; Schäfer, B.; Morestin, F.; Kärger, L.; Boisse, P.

2024. Composite Structures, 339, 118126. doi:10.1016/j.compstruct.2024.118126

Schäfer, S.; Yöndem, F. S.; Aliziyad, M. I. N. M.; Cichon, M.

2024. RSA 2023 : Tagungsband/proceedings: Aachen, Germany 22-23 November 2023, Ed.: Nießen, Nils ; Schindler, Christian, 4th International Railway Symposium Aachen (IRSA 2023), Aachen, Deutschland, 22.11.2023–23.11.2023, 726–746, RWTH Aachen University

Schäfer, S.; Greiner-Fuchs, L.; Hofmeier, T.; Koch, P.; Cichon, M.

2023. EasyChair Preprint no. 9828, 10th International Conference on Rail Operations Modelling and Analysis (2023), Belgrad, Serbien, 25.04.2023–28.04.2023, EasyChair

Greiner-Fuchs, L.; Schäfer, S.; Hofmeier, T.; Cichon, M.

2024. IRSA 2023 : Tagungsband/proceedings: Aachen, Germany 22-23 November 2023, Ed.: Nießen, Nils ; Schindler, Christian, 693–712, RWTH Aachen University. doi:10.18154/RWTH-2024-00257

Wank, J. P.; Schäfer, B.; Mitsch, J.; Kärger, L.

2024. Material Forming: ESAFORM 2024, 467–476, Materials Research Forum LLC. doi:10.21741/9781644903131-52

Mitsch, J.; Schäfer, B.; Wank, J. P.; Kärger, L.

2024. Material Forming: ESAFORM 2024, 457–466, Materials Research Forum LLC. doi:10.21741/9781644903131-51

Poppe, N.

2024, March 1. 17th World Pultrusion Conference (2024), Hamburg, Germany, February 29–March 1, 2024

Poppe, N.; Wilhelm, M.; Kärger, L.

2024. Proceedings of the 2023 International Conference on Composite Materials, Belfast, 30th July - 4th August 2023. Ed.: B. Falzon, Queen’s University Belfast

Schäfer, B.; Zheng, R.; Naouar, N.; Kärger, L.

2023. International Journal of Material Forming, 16 (6), Art.-Nr.: 68. doi:10.1007/s12289-023-01792-x

Schäfer, S.; Cichon, M. G.

2023. Dresden Rad Schiene 2023 : 19. Internationale Schienenfahrzeugtagung Dresden : 1.-3. März 2023 mit begleitender Fachausstellung : Tagungsband, 108–110, DVV Media Group

Schäfer, A.; Baranowski, M.; Springmann, M.; Hof, L.; Frölich, F.; Peter, A.; Parspour, N.; Fleischer, J.; Middendorf, P.; Kärger, L.; Michalowski, A.

2023. 12th International Conference on Power Electronics, Machines and Drives (PEMD 2023), 119–128, Institution of Engineering and Technology (IET). doi:10.1049/icp.2023.1987

Dörr, D.; Singh-Heer, N.; Xu, C.; Chang, T.; Clement-Thorne, B.; Gergely, R. C. R.; Okonski, D.; Henning, F.; Straatman, A. G.; Hrymak, A.

2023. The International Journal of Advanced Manufacturing Technology, 129 (3-4), 1159–1173. doi:10.1007/s00170-023-12017-5

Dörr, D.; Singh-Heer, N.; Gergely, R. C. R.; Schreyer, L.; Henning, F.; Straatman, A. G.; Hrymak, A.

2024. Composites Part A: Applied Science and Manufacturing, 176, Art.-Nr. 107780. doi:10.1016/j.compositesa.2023.107780

Poppe, N.; Wilhelm, M.; Kärger, L.

2023. 23rd International Conference on Composite Materials (ICCM 2023), Belfast, United Kingdom, July 30–August 4, 2023

Kärger, L.; Schäfer, F.; Werner, H. O.

2023. Material Forming 26th International ESAFORM Conference on Material Forming (ESAFORM 2023) Krakau, Polen, 19.04.2023–21.04.2023, 357–366, Materials Research Forum LLC. doi:10.21741/9781644902479-39

Poppe, C.; Kruse, M.; Kärger, L.

2023. Material Forming 26th International ESAFORM Conference on Material Forming (ESAFORM 2023) Krakau, Polen, 19.04.2023–21.04.2023, 219–230, Materials Research Forum LLC. doi:10.21741/9781644902479-24

Kruse, M.; Poppe, C. T.; Henning, F.; Ben Khalifa, N.

2023. Journal of Composite Materials, 57 (16), 2593–2608. doi:10.1177/00219983231175725

Zheng, R.; Schäfer, B.; Platzer, A.; Colmars, J.; Naim, N.; Boisse, P.

2023. Material Forming. Ed.: L. Madej, 285–292, Materials Research Forum LLC. doi:10.21741/9781644902479-31

Schäfer, B.; Zheng, R.; Philippe, B.; Kärger, L.

2023. Material Forming. Ed.: L. Madej, 331–338, Materials Research Forum LLC. doi:10.21741/9781644902479-36

Schäfer, F.; Werner, H. O.; Henning, F.; Kärger, L.

2023. Composites Part A: Applied Science and Manufacturing, 165, Art.-Nr.: 107323. doi:10.1016/j.compositesa.2022.107323

Schäfer, B.; Haas, S.; Boisse, P.; Kärger, L.

2022. Key Engineering Materials, 926, 1413–1422. doi:10.4028/p-2977b4

Poppe, C. T.; Werner, H. O.; Kruse, M.; Chen, H.; Ben Khalifa, N.; Henning, F.; Kärger, L.

2022. Key Engineering Materials, 926, 1399–1412. doi:10.4028/p-cr2tco

Meyer, N.; Werner, H. O.; Seuffert, J.; Dietrich, S.; Poppe, C.; Krauß, C.; Kärger, L.

2021, July 21. 5th International Conference on Hybrid Materials and Structures (2022), Leoben, Austria, July 20–22, 2022

Albrecht, F.; Poppe, C.; Tiemann, T.; Sauerwein, V.; Rosenberg, P.; Henning, F.

2022. Composites Science and Technology, 228, Art.-Nr.: 109574. doi:10.1016/j.compscitech.2022.109574

Frölich, F.; Dörr, D.; Jackstadt, A.; Kärger, L.

2022, July 4. 11th European Solid Mechanics Conference (2022), Galway, Ireland, July 4–8, 2022

Dietrich, S.; Seuffert, J.; Werner, H.; Meyer, N.; Poppe, C.; Krauß, C.; Kärger, L.

2022, June 9. 8th European Congress on Computational Methods in Applied Sciences and Engineering (ECCOMAS 2022), Oslo, Norway, June 5–9, 2022

Poppe, C. T.

2022. KIT Scientific Publishing. doi:10.5445/KSP/1000145625

Zimmerling, C.; Poppe, C.; Stein, O.; Kärger, L.

2022. Materials and Design, 214, Art.-Nr.: 110423. doi:10.1016/j.matdes.2022.110423

Werner, H. O.; Schäfer, F.; Henning, F.; Kärger, L.

2021. ESAFORM 2021: 24th International Conference on Material Forming, 14-16 April, online, Art.-Nr.: 2056, Université de Liège. doi:10.25518/esaform21.2056

Dörr, D.; Ivanov, S.; Gergely, R.; Meyer, N.; Henning, F.; Straatman, A. G.; Hrymak, A.

2021. ESAFORM 2021: 24th International Conference on Material Forming ; 14-16 April 2021, online, Art.-Nr.: 376, Université de Liège. doi:10.25518/esaform21.376

Poppe, C. T.

2021, November 19. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000140011

Nebe, M.; Schmack, T.; Schaefer, T.; Walther, F.

2021. Composites Part C: Open Access, 4, Art.-Nr.: 100079. doi:10.1016/j.jcomc.2020.100079

Kärger, L.; Galkin, S.; Kunze, E.; Gude, M.; Schäfer, B.

2021. ESAFORM 2021 - 24th International Conference on Material Forming, ULiège Library. doi:10.25518/esaform21.355

Schäfer, B.; Dörr, D.; Kärger, L.

2021. ESAFORM 2021 - 24th International Conference on Material Forming, ULiège Library. doi:10.25518/esaform21.883

Poppe, C.; Albrecht, F.; Krauß, C.; Kärger, L.

2021. ESAFORM 2021 - 24th International Conference on Material Forming, ID: 1938, ULiège Library. doi:10.25518/esaform21.1938

Poppe, C. T.; Krauß, C.; Albrecht, F.; Kärger, L.

2021. Composites Part A: Applied Science and Manufacturing, 145, Art.-Nr.: 106379. doi:10.1016/j.compositesa.2021.106379

Dörr, D.; Gergely, R.; Ivanov, S.; Kärger, L.; Henning, F.; Hrymak, A.

2020. Procedia manufacturing, 47, 118–125. doi:10.1016/j.promfg.2020.04.148

Poppe, C.; Albrecht, F.; Krauß, C.; Kärger, L.

2020. Procedia manufacturing, 47, 85–92. doi:10.1016/j.promfg.2020.04.141

Kärger, L.; Galkin, S.; Dörr, D.; Poppe, C.

2020. Procedia manufacturing, 47, 140–147. doi:10.1016/j.promfg.2020.04.155

Werner, H. O.; Poppe, C.; Henning, F.; Kärger, L.

2020. Procedia manufacturing, 47, 154–161. doi:10.1016/j.promfg.2020.04.160

Schäfer, B.; Dörr, D.; Kärger, L.

2020. Procedia manufacturing, 47, 134–139. doi:10.1016/j.promfg.2020.04.154

Dörr, D.

2021. KIT Scientific Publishing. doi:10.5445/KSP/1000099858

Dörr, D.; Schirmaier, F.; Joppich, T.; Fürst, T.; Kärger, L.; Henning, F.

2015. SIMULIA Regional User Meeting (2015), Aachen, Germany, November 12–13, 2015

Dörr, D.; Joppich, T.; Kugele, D.; Henning, F.; Kärger, L.

2018. Materials Science and Engineering Congress (MSE 2018), Darmstadt, Germany, September 26–28, 2018

Dörr, D.; Fengler, B.; Hohberg, M.; Kärger, L.; Henning, F.

2018. Fraunhofer Representative Office Korea 10th Anniversary Technology Seminar (2018), Seoul, South Korea, November 8, 2018

Dörr, D.; Poppe, C.; Zimmerling, C.; Krauß, C.; Schäfer, B.; Henning, F.; Kärger, L.

2018. SIMULIA Regional User Meeting (2018), Hanau, Germany, December 4, 2018

Dörr, D.; Lipowsky, L.; Schirmaier, F.; Kärger, L.; Henning, F.

2016. International Conference on Automotive Composites (ICAutoC 2016), Lisbon, Portugal, September 21–23, 2016

Dörr, D.; Schöttl, L.; Pinter, P.; Henning, F.; Kärger, L.

2019. Colloquium 602 – Composite manufacturing processes. Analyses, modelling and simulations (2019), Lyon, France, March 13–15, 2019

Dörr, D.; Lipowsky, L.; Schirmaier, F. J.; Kärger, L.; Henning, F.

2017. International journal of automotive composites, 3 (2-4, SI), 323–338. doi:10.1504/IJAUTOC.2017.091427

Poppe, C.; Zimmerling, C.; Albrecht, F.; Hüttl, J.; Fial, J.; Engelfried, M.

2017, January 31. Marktplatz Leichtbau (2017), Ludwigsburg, Germany, January 31, 2017

Poppe, C.; Dörr, D.; Kärger, L.

2019, March 13. Colloquium 602 – Composite manufacturing processes. Analyses, modelling and simulations (2019), Lyon, France, March 13–15, 2019

Poppe, C.; Fial, J.; Kärger, L.; Carosella, S.; Albrecht, F.; Zimmerling, C.; Draskovic, M.; Engelfried, M.

2017, May 30. 4. Technologietag Hybrider Leichtbau (2017), Stuttgart, Germany, May 30–31, 2017

Albrecht, F.; Zimmerling, C.; Poppe, C.; Kärger, L.; Henning, F.

2019. Key engineering materials, 809, 35–40. doi:10.4028/www.scientific.net/KEM.809.35

Dörr, D.; Joppich, T.; Kugele, D.; Henning, F.; Kärger, L.

2019. Composites / A, 125, 105508. doi:10.1016/j.compositesa.2019.105508

Dörr, D.; Kugele, D.; Joppich, T.; Henning, F.; Kärger, L.

2019. Proceedings 22nd International ESAFORM Conference on Material Forming, ESAFORM 2019; Vitoria-Gasteiz; Spain; 8 May 2019 through 10 May 2019, Art.-Nr.: 020011, American Institute of Physics (AIP). doi:10.1063/1.5112516

Poppe, C.; Dörr, D.; Kraus, F.; Kärger, L.

2019. Proceedings of the 22nd International ESAFORM Conference on Material Forming ; Vitoria-Gasteiz, Spain, 8–10 May 2019. Ed.: L. Galdos, Art.-Nr.: 020002, American Institute of Physics (AIP). doi:10.1063/1.5112507

Werner, H. O.; Dörr, D.; Henning, F.; Kärger, L.

2019. Proceedings of the 22nd International ESAFORM Conference on Material Forming ; Vitoria-Gasteiz, Spain, 8–10 May 2019. Ed.: L. Galdos, Art.-Nr.: 020019, American Institute of Physics (AIP). doi:10.1063/1.5112524

Poppe, C.; Rosenkranz, T.; Dörr, D.; Kärger, L.

2019. Composites / A, 124, Art. Nr.: 105466. doi:10.1016/j.compositesa.2019.05.034

Dörr, D.; Henning, F.; Kärger, L.

2018. Composites / A, 109, 585–596. doi:10.1016/j.compositesa.2018.03.037

Poppe, C.; Dörr, D.; Henning, F.; Kärger, L.

2018. Composites / A, 114, 327–337. doi:10.1016/j.compositesa.2018.08.018

Poppe, C.; Dörr, D.; Henning, F.; Kärger, L.

2018. Proceedings of the 21st International ESAFORM Conference on Material Forming : ESAFORM 2018 : Palermo, Italy, 23-25 April 2018. Ed.: L. Fratini, Art.Nr. 020022, American Institute of Physics (AIP). doi:10.1063/1.5034823

Dörr, D.; Faisst, M.; Joppich, T.; Poppe, C.; Henning, F.; Kärger, L.

2018. Proceedings of the 21st International ESAFORM Conference on Material Forming : ESAFORM 2018 : Palermo, Italy, 23-25 April 2018. Ed.: L. Fratini, Art.Nr. 020005, American Institute of Physics (AIP). doi:10.1063/1.5034806

Kugele, D.; Dörr, D.; Wittemann, F.; Hangs, B.; Rausch, J.; Kärger, L.; Henning, F.

2017. Proceedings of the 20th International ESAFORM Conference on Material Forming, ESAFORM 2017, Ireland, Dublin, 26th - 28th April 2017, Art.Nr. 030005, American Institute of Physics (AIP). doi:10.1063/1.5007992

Poppe, C.; Dörr, D.; Kärger, L.; Henning, F.; Joppich, T.; Henning, F.

2017. Proceedings of the 20th International ESAFORM Conference on Material Forming, ESAFORM 2017, Ireland, Dublin, 26–28 April 2017, Art.Nr. 030002, American Institute of Physics (AIP). doi:10.1063/1.5007989

Dörr, D.; Schirmaier, F. J.; Henning, F.; Kärger, L.

2017. Proceedings of the 20th International ESAFORM Conference on Material Forming, ESAFORM 2017, Ireland, Dublin, 26th - 28th April 2017, Art.Nr. 030003, American Institute of Physics (AIP). doi:10.1063/1.5007990

Schirmaier, F. J.; Dörr, D.; Henning, F.; Kärger, L.

2017. Composites / A, 102, 322–335. doi:10.1016/j.compositesa.2017.08.009

Dörr, D.; Brymerski, W.; Ropers, S.; Leutz, D.; Joppich, T.; Kärger, L.; Henning, F.

2017. Procedia CIRP, 66, 101–106. doi:10.1016/j.procir.2017.03.223

Dörr, D.; Joppich, T.; Schirmaier, F.; Mosthaf, T.; Kärger, L.; Henning, F.

2016. 17th European Conference on Composite Materials, ECCM 2016, Munich, Germany; 26. - 30. June, 2016

Dörr, D.; Schirmaier, F. J.; Henning, F.; Kärger, L.

2017. Composites / A, 94, 113–123. doi:10.1016/j.compositesa.2016.11.027

Schirmaier, F.

2017. KIT Scientific Publishing. doi:10.5445/KSP/1000064414

Dörr, D.; Joppich, T.; Schirmaier, F.; Mosthaf, T.; Kärger, L.; Henning, F.

2016. 19th International ESAFORM Conference on Material Forming (ESAFORM) Nantes; France; 27- 29 April 2016. Ed.: F. Chinesta, 170011, American Institute of Physics (AIP). doi:10.1063/1.4963567

Schirmaier, F.; Weiland, J.; Kärger, L.; Henning, F.

2014. Composites Science and Technology, 100, 19–25. doi:10.1016/j.compscitech.2014.05.033