Curing and cooling

FPRs are usually processed at temperatures above room temperature. This ensures manufacturability and, in combination with high-rate material systems, enables shorter and thus more economical cycle times.

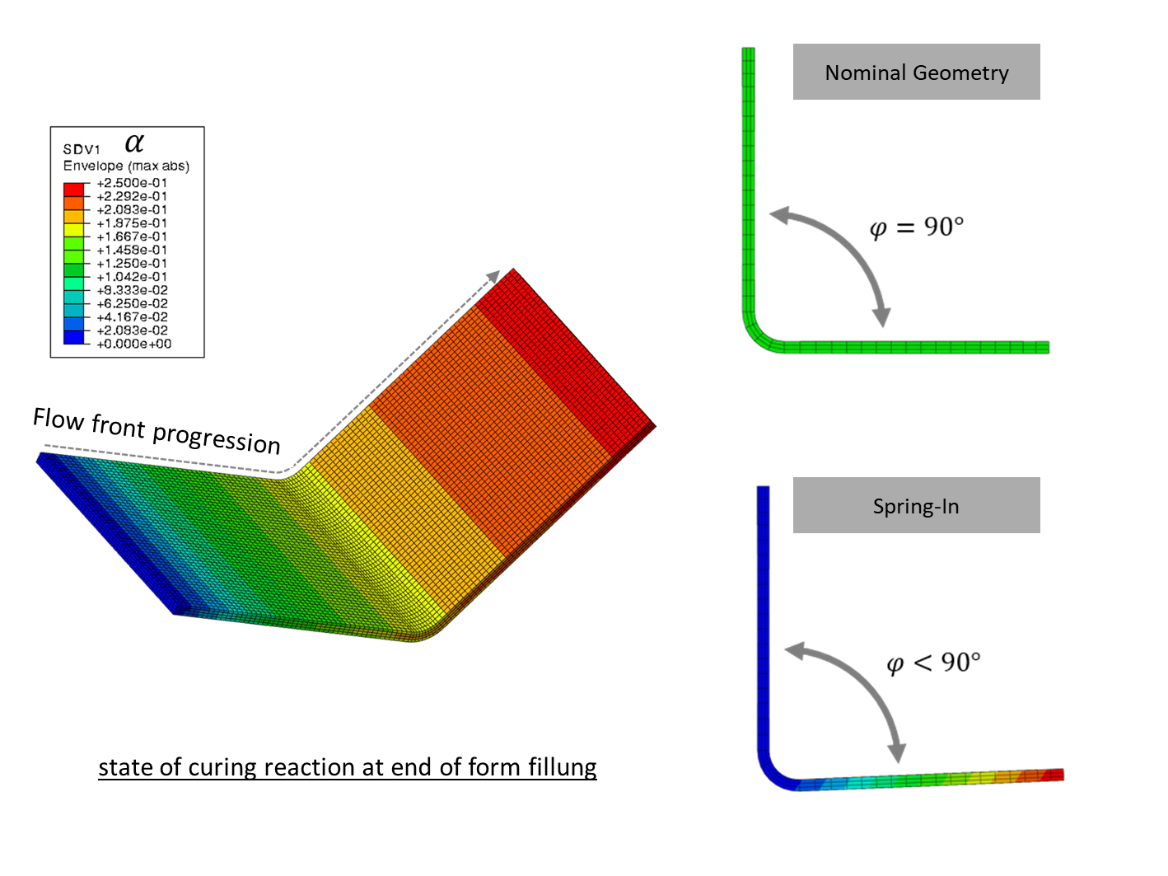

However, as a result of chemical shrinkage and thermal contraction, process-induced warpage and/or residual stresses usually occur, which can lead to non-dimensional components.

We develop material models and simulation routines that take into account the complex interaction between resin kinetics and mechanical properties, allowing prediction of warpage.

Process engineers and toolmakers can use these findings to derive measures to prevent warpage.

Research focus

- Modeling the reaction kinetics of the resin system

- Consideration of chemical shrinkage

- Macroscopic material modeling as a function of resin state

- Optimization of process parameters and geometry

Research projects |

ContactM.Sc. Felix Frölich

Dr.-Ing. Constantin Krauß |

Selected publications in the research field

Bernath, A.; Seuffert, J.; Dietrich, S.; Poppe, N.; Magagnato, D.; Wittemann, F.; Henning, F.; Kärger, L.

2024. doi:10.5281/zenodo.13327698

Bernath, A.; Kärger, L.; Henning, F.

2016. Polymers, 8 (11), 390. doi:10.3390/polym8110390