Welcome to Lightweight Engineering

Within the scope of the Excellence Initiative and in cooperation with KIT and the Fraunhofer-Gesellschaft, the Lightweight Engineering was founded at the Institute of Vehicle Systems Technology on January 1, 2009.

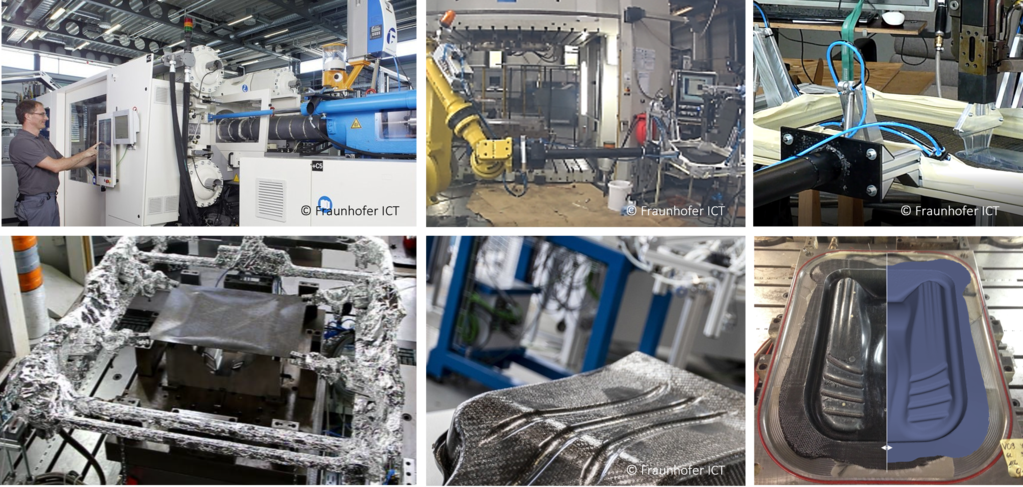

The focus of our research activities is on technologies for reducing the weight of vehicles. In this respect, lightweight construction is positioned as a cross-sectional topic and offers an interdisciplinary approach to reducing vehicle mass. Lightweight with fiber-reinforced polymers and hybrid material systems is the main focus of research at the institute. In addition to new lightweight technologies, simulation and design methods are developed to virtually optimize product development processes. Research in the field of lightweight technology is closely linked to the Polymer Engineering Department of the Fraunhofer Institute for Chemical Technology ICT in Pfinztal and the KIT Institute for Applied Materials, Materials Science KIT-IAM-WK.

If you are interested in the wide-ranging field of lightweight with its various forms of methods (simulation, design), materials (resins, fiber reinforcements, joining elements, hybrids) and technologies for production and integration of lightweight components, then we look forward to welcoming you at our institute.

To develop large-scale, lightweight and high-performance fibre composites and hybrid components, it is essential to combine competencies from the fields of methods, materials and production. Our institute develops simulation methods and integrated virtual process chains to describe the manufacturing process of fibre reinforced composites.

more

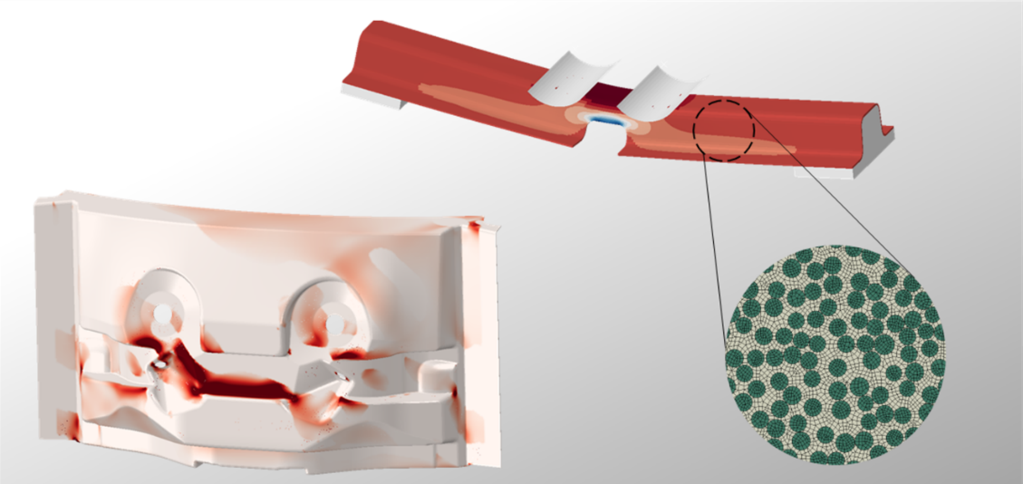

Can my component be manufactured? We develop simulation methods for complex fibre composite manufacturing processes to ensure manufacturability even before expensive tools are produced. In addition, we use the results of such process simulations in a continuous CAE chain for subsequent structural simulations.

more

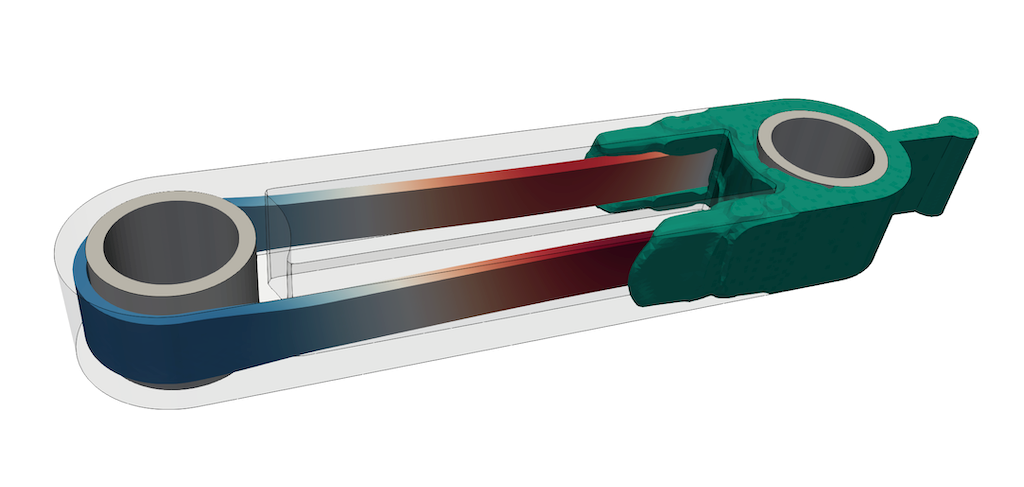

Will my component hold? We perform structural analyses for discontinuously and continuously reinforced components as well as hybrid material composites using cross-scale methods. We investigate anisotropic damage, damping behavior and the influence of manufacturing effects.

more

Every component is only as good as its semi-finished product and so is every simulation only as good as its input. We do research how we can interconnect individual simulations to form a continuous virtual process chain and then optimise component and process holistically, e.g. with the help of AI.

moreYou can find more information about the lectures of the Lightweight Construction Department here:

To the courses

October 2024: Once a year, the “Wissenschaftlicher Arbeitskreis Kunststofftechnik (WAK)” acknowledges the best scientific works in the field of plastics technology. We are delighted that M. Sc. Christina Dohmen, Dr.-Ing. Bastian Schäfer and Dr.-Ing. Constantin Krauß have won the prize!

To press release