Injection Molding

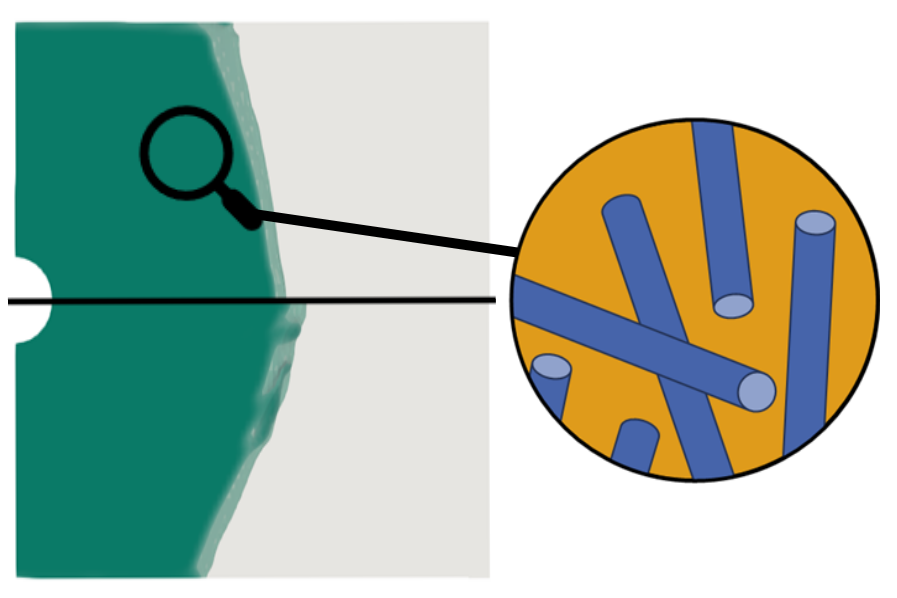

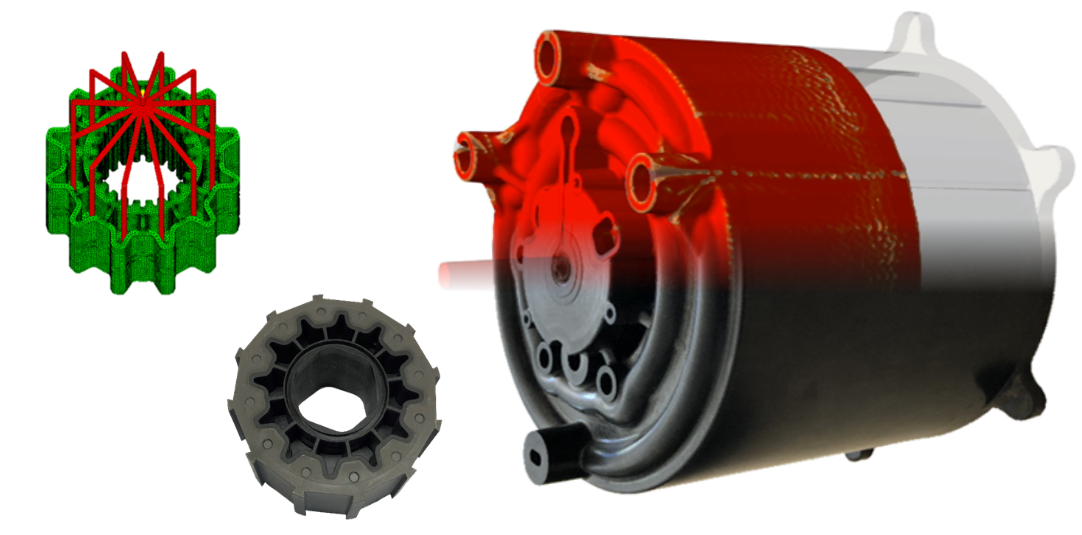

We model the mold filling process for thermoplastics and thermosets non-isothermal, transient and three-dimensional. The simulation model corresponds to the cavity in the real process. Screw chamber, plastication unit and temperature control are included as initial/boundary conditions. Process parameters such as filling rate, switchover point, material and mold temperature can be adopted. The material is simulated non-Newtonian and, in the case of fiber reinforcement, anisotropic. Key results are temperature and pressure distribution, fiber orientation and statements about weld lines, air inclusions, etc. The fiber orientation created in the process can be used for structure and warpage simulations.

Research focus

- Non-Newtonian Flow Modelling

- Anisotropic Flow

- Fiber Breakage

- Warpage

- Recycling Materials

- Close to contour tempering

- Probabilistic Simulations

Research projects |

Contact

Dr.-Ing. Florian Wittemann

M.Sc. Christina Dohmen

M.Sc. Stjepan Salatovic

|

Selected publications in the research field

Wittemann, F.; Hof, L.; Meyer, N.; Kärger, L.

2025, April 9. 14th International Conference on Manufacturing of Advanced Composites (ICMAC 2025), Coventry, United Kingdom, April 9–10, 2025

Dohmen, C.; Wittemann, F.; Kärger, L.

2025, April 9. 14th International Conference on Manufacturing of Advanced Composites (ICMAC 2025), Coventry, United Kingdom, April 9–10, 2025

Frölich, F.; Hof, L.; Zimmerling, C.; Wittemann, F.; Kärger, L.

2024. The International Journal of Advanced Manufacturing Technology. doi:10.1007/s00170-024-14913-w

Wittemann, F.; Krauß, C.; Kärger, L.

2025. Applied Composite Materials, 32 (1), 149–172. doi:10.1007/s10443-024-10268-3

Jetty, B.; Wittemann, F.; Kärger, L.

2024. Polymers, 16 (16), Art.-Nr.: 2245. doi:10.3390/polym16162245

Wittemann, F.; Bernath, A.; Meyer, N.; Kärger, L.

2024. Proceedings of the 21st European Conference on Composite Materials (ECCM 2024). Ed.: C. Binetruy. Vol. 5, 139–145, European Society for Composite Materials (ESCM)

Dietrich, S.; Dohmen, C.; Frölich, F.; Jackstadt, A.; Wittemann, F.; Kärger, L.

2024. Proceedings of the 21st European Conference on Composite Materials. Vol 2 Material Science. Ed.: C. Binetruy, 548–554, European Society for Composite Materials (ESCM)

Bernath, A.; Seuffert, J.; Dietrich, S.; Poppe, N.; Magagnato, D.; Wittemann, F.; Henning, F.; Kärger, L.

2024. doi:10.5281/zenodo.13327698

Olma, M.; Meyer, N.; Krauß, C.; Wittemann, F.; Kärger, L.

2024, July 5. 21st European Conference on Composite Materials (ECCM 2024), Nantes, France, July 2–5, 2024

Dohmen, C.; Meyer, N.; Haas, J.; Beck, B.; Wittemann, F.; Kärger, L.

2024, July 5. 21st European Conference on Composite Materials (ECCM 2024), Nantes, France, July 2–5, 2024

Hof, L.; Frölich, F.; Wittemann, F.; Kärger, L.

2024, July 2. 21st European Conference on Composite Materials (ECCM 2024), Nantes, France, July 2–5, 2024

Poppe, N.; Zeeb, G.; Wittemann, F.; Wilhelm, M.; Kärger, L.

2024, July 3. 21st European Conference on Composite Materials (ECCM 2024), Nantes, France, July 2–5, 2024

Frölich, F.; Bechtloff, L.; Scheuring, B. M.; Heuer, A. L.; Wittemann, F.; Kärger, L.; Liebig, W. V.

2025. Progress in Additive Manufacturing, 10 (2), 1217–1229. doi:10.1007/s40964-024-00700-2

Wittemann, F.; Kärger, L.

2023. 23rd International Conference on Composite Materials : (ICCM 23) held in Belfast, Northern Ireland, from July 30th to August 4th 2023, Queen’s University Belfast

Wittemann, F.; Kärger, L.

2023. NAFEMS-Magazin, 68 (4), 22–28

Liebig, W.; Muth, M.; Seitz, M.; Wittemann, F.; Weiss, P.

2022. ECCM20 - Proceedings of the 20th European Conference on Composite Materials - Composites Meet Sustainability (Vol 1-6), Ed.: A. Vassilopoulos, 1110–1117, École Polytechnique Fédérale de Lausanne (EPFL)

Wittemann, F.; Maertens, R.; Henning, F.; Kärger, L.

2022. Composites Meet Sustainability - Proceedings of the 20th European Conference on Composite Materials. Ed.: A. Vassilopoulos, École Polytechnique Fédérale de Lausanne (EPFL)

Wittemann, F.; Kärger, L.; Henning, F.

2022. Journal of Non-Newtonian Fluid Mechanics, 310, 104950. doi:10.1016/j.jnnfm.2022.104950

Kesten, J.; Frölich, F.; Wittemann, F.; Knirsch, J.; Bechler, F.; Kärger, L.; Eberhard, P.; Henning, F.; Doppelbauer, M.

2022. 2022 International Conference on Electrical Machines (ICEM), Valencia, Spain, 05-08 September 2022, 2304–2310, Institute of Electrical and Electronics Engineers (IEEE). doi:10.1109/ICEM51905.2022.9910780

Bechler, F.; Kesten, J.; Wittemann, F.; Henning, F.; Doppelbauer, M.; Eberhard, P.

2021. International Journal of Mechanical System Dynamics, 1 (1), 89–95. doi:10.1002/msd2.12005

Wittemann, F.

2022. KIT Scientific Publishing. doi:10.5445/KSP/1000148499

Wittemann, F.

2022, February 16. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000142956

Wittemann, F.; Kärger, L.; Henning, F.

2021. Composites. Part C, Open access, 5, Art.-Nr. 100152. doi:10.1016/j.jcomc.2021.100152

Wittemann, F.; Maertens, R.; Bernath, A.; Hohberg, M.; Kärger, L.; Henning, F.

2018. Journal of composites science, 2 (1), Aritcle no: 5. doi:10.3390/jcs2010005

Wittemann, F.; Maertens, R.; Kärger, L.; Henning, F.

2019. Composites / A, 124, 105476. doi:10.1016/j.compositesa.2019.105476