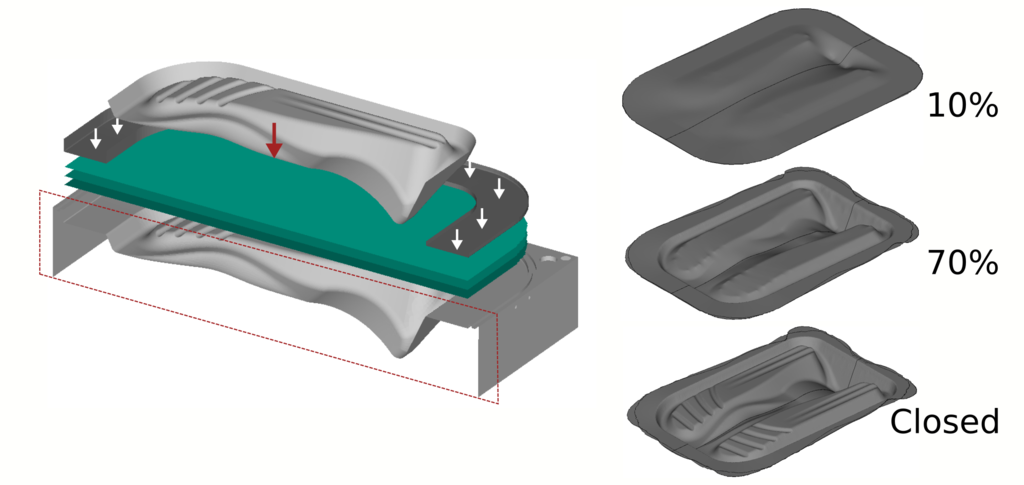

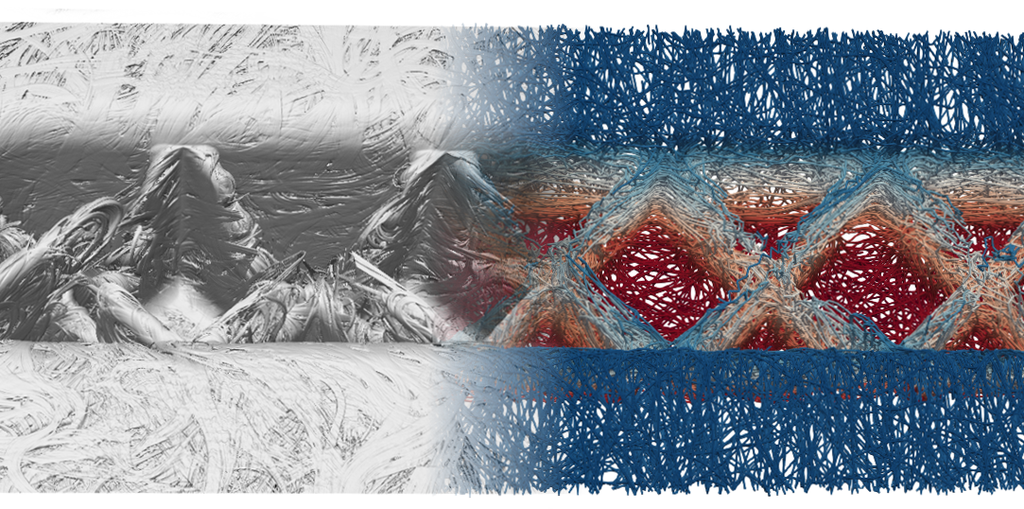

During forming (draping) processes, stacked plies of dry, infiltrated or pre-impregnated semi-finished products are formed into a complex three-dimensional shape using matching molds.. We investigate the forming behavior in order to predict occurring effects and potential defects by means of simulation model.

more

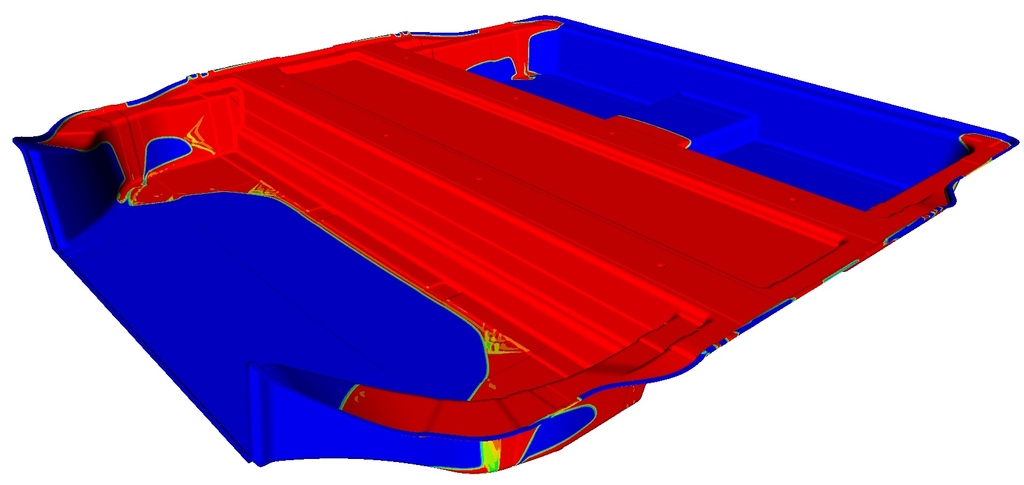

In the RTM process, semi-finished fibre products are infiltrated with a plastic resin under pressure in a closed, two-part mould. We investigate the fillability of different geometries based on the flow front of the resin with the aim of minimising filling time and cavity pressure.

more

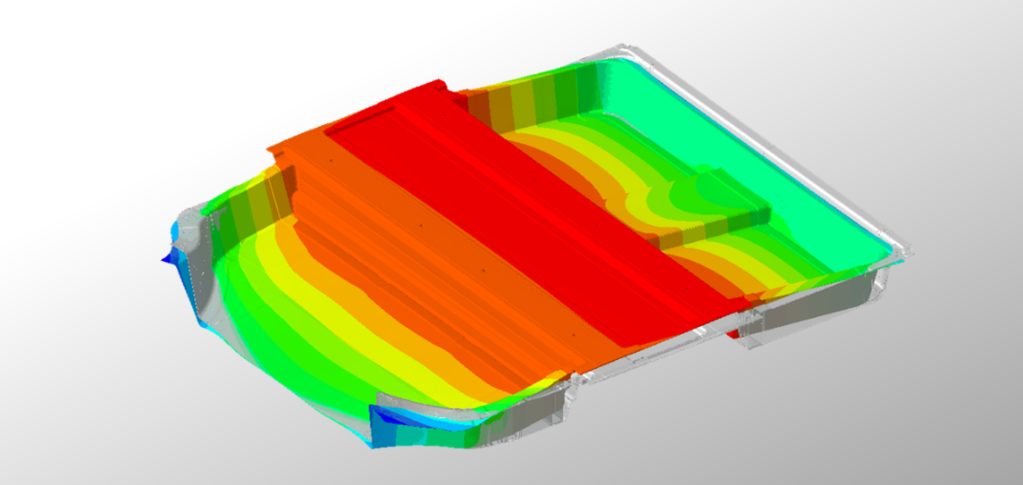

From process to room temperature: We predict distortion and residual stress as a result of chemical shrinkage and thermal contraction to ensure component dimensional stability. Our approach takes reaction and crystallization kinetics into account.

more

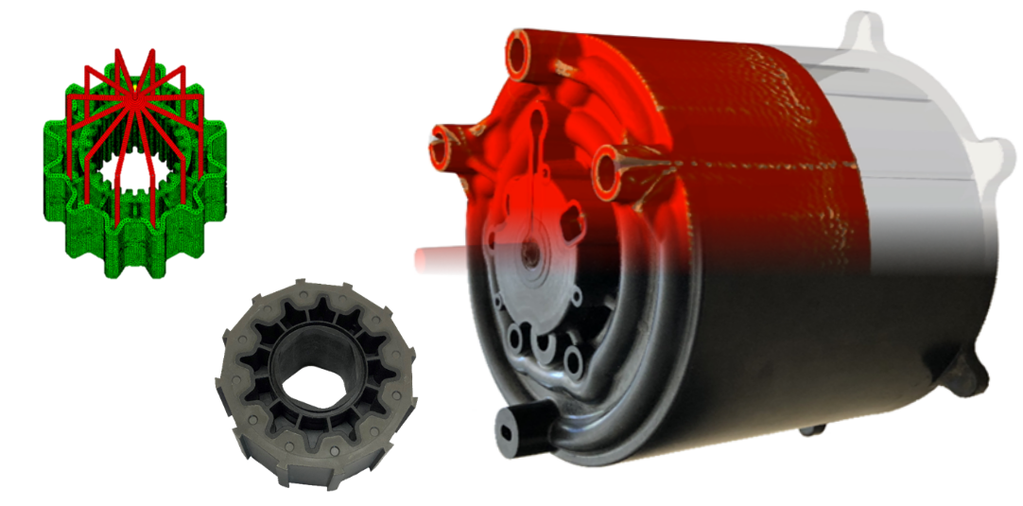

We simulate the injection molding process using a non-Newtonian, anisotropic multiphase approach. Fiber orientation and fiber breakage are considered. Advanced anisotropic warpage simulations based on fiber orientation and curing state at the end of the mold filling process are possible.

more

Compression molding is a manufacturing process for discontinuous fiber reinforces polymers. The mechanical properties of such parts depend on the production process and only process simulation allows a reliable prediction of part properties.

more

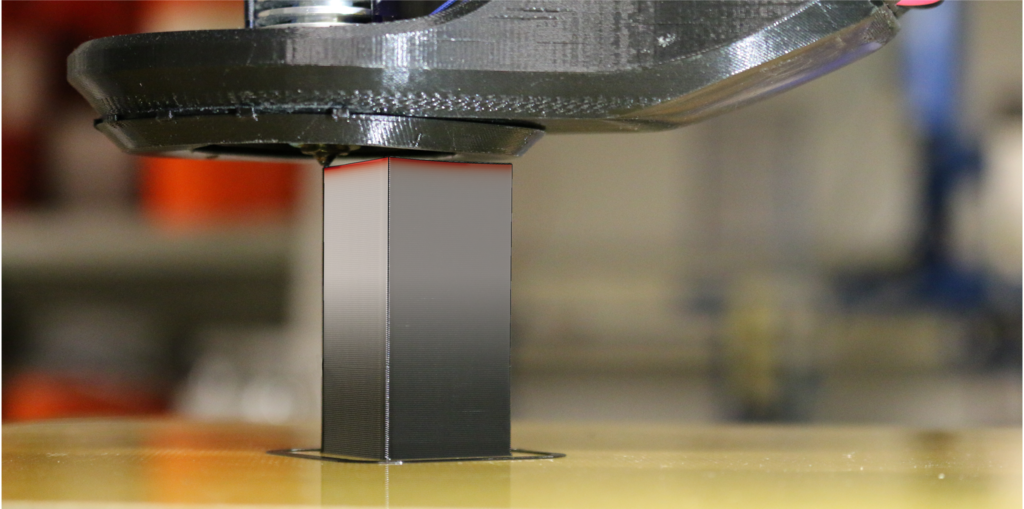

We research new methods for simulation and design of innovative additive manufacturing processes on different scale levels. In this context, we not only conduct research on individual processes, but also deal with process hybridization in the context of additive manufacturing.

more