Development of a methodology for the detection of forming defects in continuous fiber-reinforced thermoplastics using optical image processing

- type:Master thesis

- time:immediately

- tutor:

Development of a methodology for the detection of forming defects in continuous fiber-reinforced thermoplastics using optical image processing

Motivation

Due to the combination of advantages such as high lightweight construction potential, recyclability, weldability and, in particular, short cycle times in component production, continuous fiber-reinforced thermoplastics are increasingly being used in aviation. The stamp forming process can be used to manufacture the components. However, the aviation industry in particular places the highest demands on component quality and forming defects, which can be partially tolerated in other industries, must be avoided through optimized process control. However, some forming defects can only be identified with great effort and in expensive test procedures. For rapid process optimization, however, a way is needed to detect and quantify forming defects quickly, cost-effectively and reliably.

Project description:

The task will be carried out in close cooperation with the supervising research assistant. You will be supported by our technical staff at all times during the practical activities.

The master's thesis is carried out as part of the DFG research project FOR5339 "AI-based Methodology for the Fast Maturation of Immature Manufacturing Processes".

Work content:

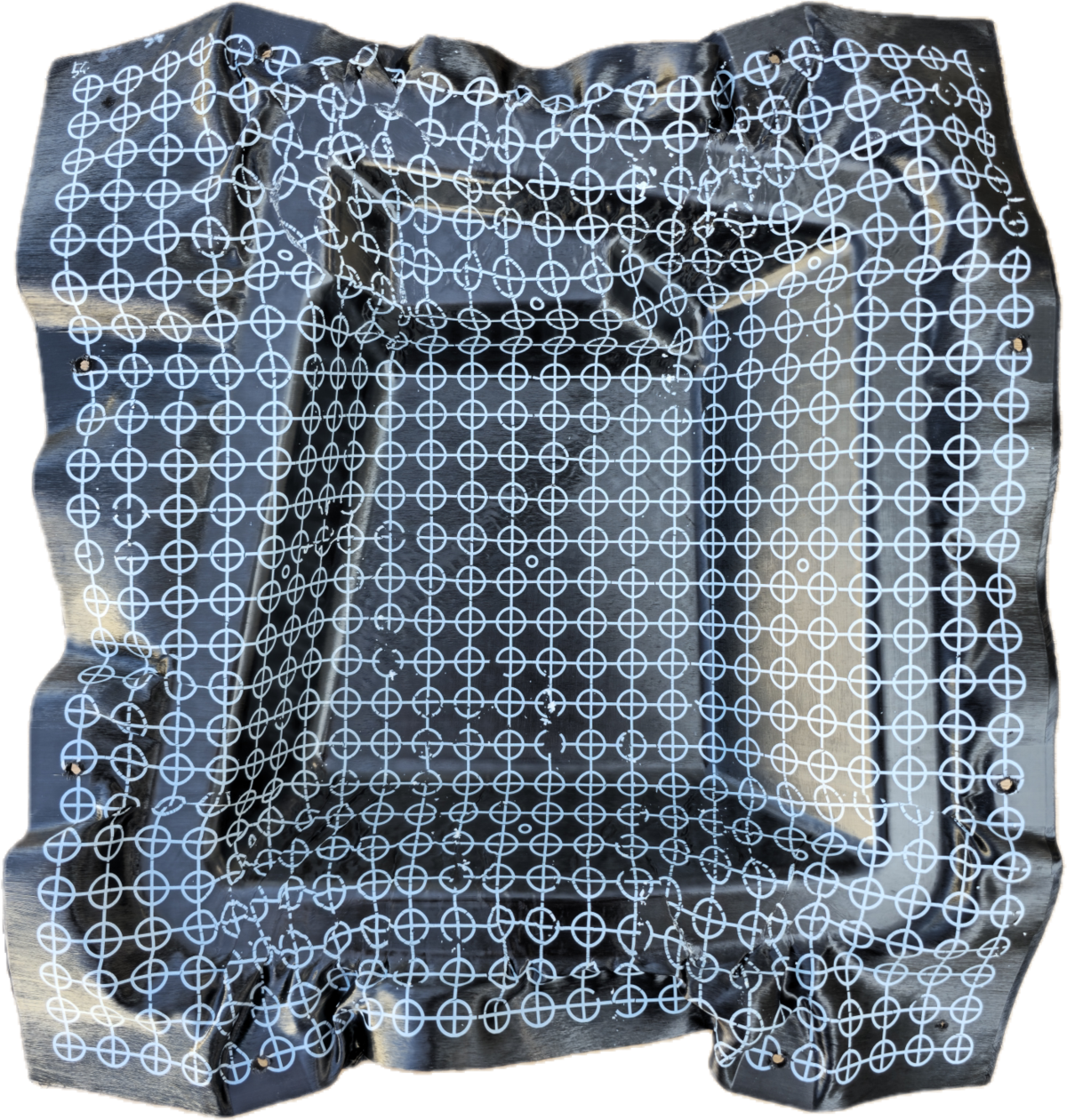

- Literature research on different surface patterns and optical image processing methods

- Evaluation of different patterns with regard to various restrictions and criteria

- Application of suitable surface patterns to test material and forming of the samples using the stamp forming process

- Analysis of the formed patterns and detection of artifacts using optical image processing

- Validation of the methodology based on the test results

Start: immediately

Location: Pfinztal Berghausen

Contact: Georg Zeeb, M.Sc.

E-mail: georg zeeb ∂does-not-exist.ict fraunhofer de